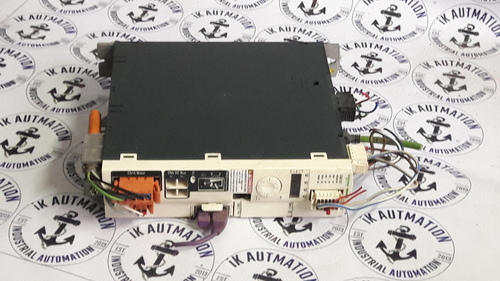

SCHNEIDER pacDrive C200

Price 7000 INR/ Piece

MOQ : 1 Piece

SCHNEIDER pacDrive C200 Specification

- Efficiency

- 96%

- IP Rating

- IP20

- Surface Finish

- Powder Coated

- Operating Temperature

- 0C to +55C

- Insulation Material

- High-grade Polymer

- Humidity %

- 5% to 95% (non-condensing)

- Connector Type

- Screw Type Terminal Block

- Shape

- Rectangular

- Power Factor

- >0.9

- Mounting Type

- Panel Mounting

- Feature

- High-performance motion and logic control

- Overheating Protection

- YES

- Product Type

- Programmable Automation Controller (PAC)

- Application

- Industrial Automation, Motion Control, Packaging Machines

- Protection Level

- EN 61131-2, CE Certified

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 24 V DC

- Energy Consumption

- Low Power Consumption

- Output Type

- Digital & Analog Outputs

- Color

- Grey

- Dimension (L*W*H)

- 226 x 89 x 220 mm

- Weight

- 2.5 kg

- Phase

- Three Phase

- Input Voltage

- 24 V DC

- Size

- Standard

- Material

- Metal, Plastic

- Connection Type

- Modular Terminal

SCHNEIDER pacDrive C200 Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Cash Advance (CA), Days after Acceptance (DA), Cash in Advance (CID), Cheque

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- AS PER CUSTOMER

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- SCHNEIDER pacDrive C200

About SCHNEIDER pacDrive C200

Experience the elite engineering of the SCHNEIDER pacDrive C200, a commanding solution for pivotal industrial automation demands. Powered by a redoubtable Intel x86 1.2 GHz processor and fortified with 512 MB RAM and 256 MB Flash, this unit ensures relentless performance. Multiple communication ports, advanced protocols, and high safety with integrated SIL3/PLe Safe Torque-Off functionality establish a redoubtable presence in motion control systems. Benefit from dealer and wholesaler discounts for the best price on this robust, energy-efficient platform, designed to empower diverse automation scenarios.

Optimal Suitability & Material Highlights

Tailored for industrial automation, motion control, and packaging machinery, the SCHNEIDER pacDrive C200 thrives in demanding environments. Its sturdy rectangular body, formed from resilient metal and high-grade polymer, ensures durability. The powder-coated finish and IP20 rating provide security and longevity. With digital and analog outputs, this device is suitable for sophisticated applications that demand high-performance motion and logic control, making it essential for manufacturers, exporters, distributors, and service providers seeking reliability.

Packaging, Certifications & Sample Dispatch Process

Each SCHNEIDER pacDrive C200 is carefully dispatched in secure, standard packaging designed to preserve its integrity in transit. Dispatching is managed for swift and safe delivery. The product comes with CE and EN 61131-2 certifications, ensuring compliance with global industrial standards. Sample units can be provided for evaluation or exchange, upon request, to guarantee suitability before bulk procurement. Every packaging process is streamlined to uphold quality from the manufacturer to the end user.

Optimal Suitability & Material Highlights

Tailored for industrial automation, motion control, and packaging machinery, the SCHNEIDER pacDrive C200 thrives in demanding environments. Its sturdy rectangular body, formed from resilient metal and high-grade polymer, ensures durability. The powder-coated finish and IP20 rating provide security and longevity. With digital and analog outputs, this device is suitable for sophisticated applications that demand high-performance motion and logic control, making it essential for manufacturers, exporters, distributors, and service providers seeking reliability.

Packaging, Certifications & Sample Dispatch Process

Each SCHNEIDER pacDrive C200 is carefully dispatched in secure, standard packaging designed to preserve its integrity in transit. Dispatching is managed for swift and safe delivery. The product comes with CE and EN 61131-2 certifications, ensuring compliance with global industrial standards. Sample units can be provided for evaluation or exchange, upon request, to guarantee suitability before bulk procurement. Every packaging process is streamlined to uphold quality from the manufacturer to the end user.

FAQ's of SCHNEIDER pacDrive C200:

Q: How does the SCHNEIDER pacDrive C200 benefit industrial automation setups?

A: The pacDrive C200 offers high-performance motion and logic control, multi-protocol communication, and integrated safety functions such as Safe Torque-Off (up to SIL3/PLe), ensuring both flexibility and safety across complex automation processes.Q: What applications is the SCHNEIDER pacDrive C200 most suitable for?

A: It is tailored for industrial automation, packaging machinery, and motion control applications where reliability, scalability (up to 99 axes), and robust communication protocols are essential for operational excellence.Q: Where can the SCHNEIDER pacDrive C200 be installed for optimal performance?

A: Designed for panel mounting, the device performs optimally in industrial settings that require secure, modular installation, reliable environmental protection (IP20), and efficient operation in temperatures from 0C to +55C.Q: What is the process for obtaining a sample or exchanging the SCHNEIDER pacDrive C200?

A: Samples can be dispatched upon request, and the exchange process is facilitated through authorized dealers, distributors, or directly from the manufacturer, ensuring timely, secure delivery and evaluation.Q: How does the device manage overheating and power efficiency?

A: With a passive cooling system, 96% efficiency, low power consumption (25 W max), and effective overheating protection, the pacDrive C200 is engineered for energy savings and uninterrupted, safe operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in schneider servo drive and servo motor Category

SCHNEIDER LXM32AU90M2

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Output Type : Digital/Analog

Color : Grey

Connector Type : Screw Terminal

Product Type : Servo Drive

SCHNEIDER LXM32AD30N4

Price 10500 INR / Piece

Minimum Order Quantity : 1 Piece

Output Type : Three Phase

Color : Grey

Connector Type : Screw Terminal Block

Product Type : Servo Drive

SCHNEIDER TCSESM083F23F1

Price 7000 INR / Piece

Minimum Order Quantity : 1 Piece

Output Type : Ethernet Ports

Color : Green/Black

Connector Type : RJ45

Product Type : Managed Ethernet Switch

SCHNEIDER TM238LDD24DT

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Output Type : Transistor

Color : Grey

Connector Type : Removable terminal blocks

Product Type : PLC Controller

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry