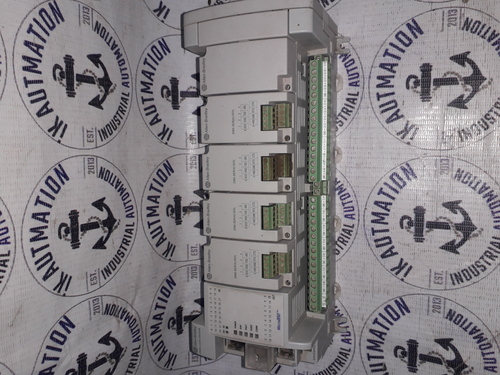

ALLEN BRADLEY 1747-ASB

Price 3000 INR/ Piece

ALLEN BRADLEY 1747-ASB Specification

- Operating Temperature

- 0C to 60C

- Mounting Type

- Rack/DIN Rail Mount

- Efficiency

- High

- Shape

- Rectangular

- Humidity %

- 5% to 95% non-condensing

- Surface Finish

- Powder Coated

- Insulation Material

- Enclosure Insulated

- Feature

- Hot Swappable, Diagnostic LEDs

- Overheating Protection

- YES

- IP Rating

- IP20

- Connector Type

- Ribbon Cable Connector

- Product Type

- Remote I/O Adapter Module

- Application

- PLC System Expansion

- Protection Level

- Standard

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 5V DC

- Energy Consumption

- Low Power Consumption

- Output Type

- Digital

- Color

- Grey

- Dimension (L*W*H)

- 175 mm x 110 mm x 38 mm

- Weight

- 375g

- Phase

- Single Phase

- Input Voltage

- 5V DC from SLC Backplane

- Size

- Standard

- Connection Type

- Backplane, Remote I/O Cable

- Material

- Industrial Grade PCB, Enclosure: Metal

- Model Number

- 1747-ASB

- Diagnostic LEDs

- Yes

- Series

- SLC 500

- Enclosure Type

- Open Type

- Baud Rate

- 57.6 Kbps or 115.2 Kbps

- Max Expansion Slots

- Up to 30 I/O Slots

- Communication Protocol

- Remote I/O

- Power Supply

- Supplied by SLC Rack

- Standards

- IEC 61131

- Storage Temperature

- -40°C to 85°C

- Operating System Compatibility

- RSLogix, FactoryTalk

ALLEN BRADLEY 1747-ASB Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- AS PER CUSTOMER

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ALLEN BRADLEY 1747-ASB

About ALLEN BRADLEY 1747-ASB

Optimized Usage & Applications in Industrial Plants

The ALLEN BRADLEY 1747-ASB is designed for expanding PLC systems in manufacturing plants. Its use type supports both rack and DIN rail mounting, making it adaptable within complex automation layouts. With a standard size and hot-swappable functionality, this module enables maintenance teams to upgrade or replace units without stopping operations. Suitable for process plants and assembly lines, its reliable integration streamlines control and data acquisition, ensuring high uptime in demanding applications such as automotive, packaging, and material handling.

Market Value, Delivery, and Packaging Excellence

The ALLEN BRADLEY 1747-ASB holds strong market value in Japans domestic market among dealers, distributors, and exporters. Quotation requests are managed efficiently, reflecting the products demand and reliability. Delivery time is prompt, typically finalized within days, with handover scheduled on mutually agreed terms. Packaging details ensure secure transit: the module is powder-coated, insulated, and encased in industry-standard packaging that prevents damage. Reliable logistics and careful handling elevate customer confidence in every transaction.

FAQs of ALLEN BRADLEY 1747-ASB:

Q: How does the ALLEN BRADLEY 1747-ASB benefit PLC system expansion in industrial environments?

A: The module allows for seamless addition of up to 30 I/O slots, supporting high efficiency and scalability in PLC control applications. Its hot-swappable feature reduces downtime and streamlines system upgrades or repairs.Q: What communication protocol is used by the ALLEN BRADLEY 1747-ASB?

A: The 1747-ASB utilizes the Remote I/O protocol, enabling robust and flexible connectivity within the SLC 500 Series for industrial automation tasks.Q: When is the best time to use the 1747-ASB module in a manufacturing plant?

A: Its ideal during system expansions, upgrades, or routine maintenance when additional I/O capacity or improved diagnostics are required without requiring process shutdowns.Q: Where can the ALLEN BRADLEY 1747-ASB be mounted?

A: The module supports both rack and DIN rail mounting, providing versatile installation options within plant control panels or automation cabinets.Q: What is the process for requesting a quotation and handover of the ALLEN BRADLEY 1747-ASB?

A: Customers in Japan initiate quotes through authorized channels. After acceptance, delivery and handover are scheduled to ensure swift and secure product receipt, followed by detailed packaging for safe transit.Q: What operating system is compatible with the 1747-ASB?

A: The 1747-ASB is compatible with RSLogix and FactoryTalk operating systems, facilitating smooth configuration and integration into existing PLC infrastructures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ALLEN BRADLEY PLC AND HMI Category

ALLEN BRADLY 1606-XLE240E

Price 6000 INR / Piece

Minimum Order Quantity : 1 Piece

Rated Voltage : 24V DC Output

Product Type : DIN Rail Power Supply

Connector Type : Screw Type

Material : Metal/Plastic

ALLEN-BRADLEY 1794-TB3G

Price 4000 INR / Piece

Minimum Order Quantity : 1 Piece

Rated Voltage : 125V AC/DC

Product Type : Terminal Base

Connector Type : Terminal Block

Material : Plastic, Metal

ALLEN BRADLEY 9300-RADM1

Price 10500 INR / Piece

Minimum Order Quantity : 1 Piece

Rated Voltage : 24 V DC

Product Type : Industrial Ethernet Serial Modem

Connector Type : RJ45, DB9 Serial

Material : ABS Plastic / Metal

ALLEN-BRADLEY 2080-LC50-48QWB

Price 6000 INR / Piece

Minimum Order Quantity : 1 Piece

Rated Voltage : 24V DC

Product Type : Micro850 PLC Controller

Connector Type : Screw Terminal Block

Material : Plastic, Metal

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry