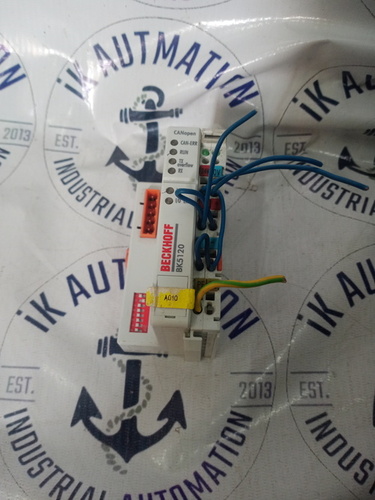

BECKHOFF KL5111

BECKHOFF KL5111 Specification

- Overheating Protection

- NO

- Insulation Material

- Polycarbonate

- Operating Temperature

- 0C to +55C

- Feature

- 1-channel encoder interface with integrated 24 V supply, Diagnostic LEDs, Hot swap (in EtherCAT systems)

- Humidity %

- 95% (non-condensing)

- Efficiency

- Standard

- Surface Finish

- Matte

- Connector Type

- Spring Cage Plug Connection

- Mounting Type

- DIN Rail Mounting

- IP Rating

- IP20

- Shape

- Rectangular

- Product Type

- KL5111 Encoder Interface Terminal

- Application

- Industrial Automation, Position Detection

- Protection Level

- Standard

- Frequency (MHz)

- 0-250 kHz (Encoder Signal Frequency)

- Rated Voltage

- 24 V DC (-15%/+20%)

- Energy Consumption

- Approx. 600 mW

- Output Type

- Digital

- Color

- Light Gray

- Dimension (L*W*H)

- approx. 100 mm x 12 mm x 68 mm

- Weight

- Approx. 65 g

- Input Voltage

- 24 V DC

- Size

- Standard I/O Terminal Size

- Phase

- Single Phase

- Material

- Plastic, Metal

- Connection Type

- Spring Cage Terminal

- No Of Poles

- 1

- System Bus

- K-bus

- Interface

- RS422/TTL (Differential)

- Maximum Cable Length

- 100 m (for encoder connection)

- Signal Type Supported

- Incremental Encoder (A, B, C inputs)

- Relative Humidity

- up to 95% (no condensation)

- Storage Temperature

- -25°C to +85°C

- Number of Channels

- 1

- Diagnostic Indicators

- Status LEDs for Channel and Error

BECKHOFF KL5111 Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C)

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- AS PER CUSTOMER

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- BECKHOFF KL5111

About BECKHOFF KL5111

General and Specific Applications of BECKHOFF KL5111

The BECKHOFF KL5111 excels in general industrial automation and position detection, offering reliable incremental encoder support for precise control. Beyond standard plant automation systems, its also ideal for use in complex assembly lines, robotics, and motion control centers. The terminals rugged design allows it to function seamlessly in various plant applications, delivering consistent performance and unmatched integration capacity, especially where robust signal acquisition and diagnostics are crucial. Its versatility makes it suitable for both specialized and broad automation scenarios.

Export Markets, Transport, and Certification Details

The BECKHOFF KL5111 is a sought-after export product with primary markets spanning Europe, Asia, and North America. Proposal amounts typically consider FOB ports in Germany, ensuring efficient transportation logistics and delivery schedules. Estimates for lead times and shipping can vary based on the chosen port and destination. Certified to meet stringent international standards, this terminal is trusted by dealers, distributors, and service providers worldwide, giving assurance of both consistent performance and regulatory compliance during export and import processes.

FAQs of BECKHOFF KL5111:

Q: How does the BECKHOFF KL5111 support industrial automation processes?

A: The BECKHOFF KL5111 interfaces with incremental encoders, transmitting precise position and movement data for industrial automation systems. Its diagnostic LEDs and integrated channel error indicators help streamline troubleshooting and maintain operational efficiency.Q: What are the main benefits of using the KL5111 in plant applications?

A: The KL5111 offers robust signal acquisition, supports long cable lengths (up to 100 meters), and operates under harsh environmental conditions, making it ideal for plant automation. Its reliability ensures accurate data acquisition for motion control and position detection.Q: When should you choose the KL5111 over other encoder interfaces?

A: Choose the KL5111 when you require a one-channel, cost-effective, and compact encoder interface compatible with RS422/TTL signals and incremental encoders, particularly where diagnostics and easy integration with standard DIN rail mounting are essential.Q: Where can the KL5111 be installed for optimal performance?

A: Install the KL5111 within industrial automation control panels using standard DIN rail mounting. Its compact size and IP20 rating ensure safe integration inside protected enclosures, making it suitable for a range of automation and control systems.Q: What is the process for connecting encoders to the KL5111?

A: Connect your incremental encoder to the KL5111 using the spring cage terminal. Ensure the total cable length does not exceed 100 meters, and verify connections with the integrated diagnostic LEDs for channel status and error monitoring.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in BECKHOFF PLC AND HMI Category

BECKHOFF KL 1012

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Humidity % : 95% (noncondensing)

Feature : Shortcircuit proof outputs, Diagnostics LEDs

Operating Temperature : 0C to +55C

Output Type : Digital (2channel output)

BECKHOFF BK9050

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Humidity % : 95 % (noncondensing)

Feature : AutoBaud detection, Diagnostics LEDs

Operating Temperature : 0C to +55C

Output Type : Digital and Analog Signals

BECKHOFF BK5120

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Humidity % : 95% max. (noncondensing)

Feature : Modular design, Easy Integration, Fast Data Transmission

Operating Temperature : 0C to +55C

Output Type : Digital

BECKHOFF KL5101

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Humidity % : 95% (noncondensing)

Feature : PWM output terminal with integrated diagnostics

Operating Temperature : 0 C to +55 C

Output Type : Digital output, PWM signal

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry