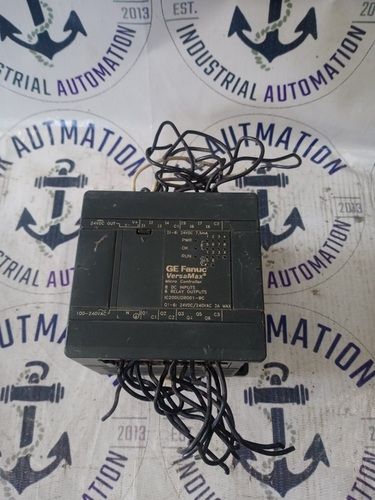

GE Fanuc IC693CPU311W PLC

Price 20000 INR/ Piece

MOQ : 1 Piece

GE Fanuc IC693CPU311W PLC Specification

- Power Factor

- High

- Overheating Protection

- YES

- Efficiency

- Reliable Performance

- Surface Finish

- Matte

- IP Rating

- IP20

- Insulation Material

- High Grade Plastic

- Humidity %

- 5% - 95% (non-condensing)

- Mounting Type

- DIN Rail or Panel Mount

- Connector Type

- Screw Terminal

- Operating Temperature

- 0°C to 60°C

- Feature

- Expandable I/O, LED Status Indication

- Shape

- Rectangular

- Product Type

- Programmable Logic Controller (PLC)

- Application

- Industrial Automation, Process Control

- Protection Level

- NEMA Type 1

- Frequency (MHz)

- 50/60 Hz

- Rated Voltage

- 120/240 VAC

- Energy Consumption

- Minimal, typically <10 W

- Output Type

- Digital

- Color

- Black / Grey

- Dimension (L*W*H)

- 118 mm x 132 mm x 70 mm

- Weight

- Approx. 400 g

- Phase

- Single Phase

- Size

- Standard

- Input Voltage

- 24 VDC

- Material

- Industrial Polymer / Metal Frame

- Connection Type

- Terminal Block

- Status Indicators

- LEDs for Power, Run, Fault, I/O

- Storage Temperature

- -40°C to +85°C

- I/O Points

- Up to 1024

- Battery Backup

- Yes

- Scan Rate

- 1 ms/kbyte

- Part Number

- IC693CPU311W

- Communication Ports

- Serial RS-485

- Programming Software

- Proficy Machine Edition, Logicmaster 90-30

- Processor

- 8031 Microprocessor

- CPU Memory

- 12K Bytes User Memory

- Expansion Capability

- Yes, with additional modules

- Relays Type

- Solid State/Relay (depends on module)

GE Fanuc IC693CPU311W PLC Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Cash Against Delivery (CAD), Cash on Delivery (COD), Cheque, Telegraphic Transfer (T/T), Paypal, Western Union, Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Days after Acceptance (DA), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Hours

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- AS PER CUSTOMER

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Asia, Central America, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

- Certifications

- GE FANUC IC693CPU311W

About GE Fanuc IC693CPU311W PLC

Select the GE Fanuc IC693CPU311W PLC for your industrial automation needs and take advantage of its unparalleled reliability and exquisite engineering. This praiseworthy PLC, featuring a 12K Bytes user memory and a powerful 8031 microprocessor, can manage up to 1024 I/O points with minimal energy consumption (<10 W). Equipped with LED status indicators, solid-state/relay modules, and a rugged black/grey case, it offers expandability and versatile mounting. With its NEMA Type 1 protection and high-grade plastic insulation, this featured controller ensures safe, efficient operation across challenging environments.

Usage & Application Highlights

The GE Fanuc IC693CPU311W PLC is widely utilized in process control and industrial automation applications, offering reliable performance in variable climates. Designed for easy DIN rail or panel mounting, it adapts to a range of machinery and equipment surfaces, thanks to its matte industrial polymer frame. Best suited for environments requiring rapid logic execution, operators should follow detailed programming instructions in Proficy Machine Edition or Logicmaster 90-30 for safe startup and optimal functionality.

Supply, Packing & Transport Services

We ensure a robust supply ability for the GE Fanuc IC693CPU311W PLC, catering to wholesale, retail, and export markets across Germany. Each unit is securely packed using industrial-grade materials to prevent transit damage during transportation. Our packing & dispatch team coordinates timely shipments using reliable transport services, covering main domestic markets and ensuring on-schedule delivery to dealers, distributors, traders, and service providers nationwide.

Usage & Application Highlights

The GE Fanuc IC693CPU311W PLC is widely utilized in process control and industrial automation applications, offering reliable performance in variable climates. Designed for easy DIN rail or panel mounting, it adapts to a range of machinery and equipment surfaces, thanks to its matte industrial polymer frame. Best suited for environments requiring rapid logic execution, operators should follow detailed programming instructions in Proficy Machine Edition or Logicmaster 90-30 for safe startup and optimal functionality.

Supply, Packing & Transport Services

We ensure a robust supply ability for the GE Fanuc IC693CPU311W PLC, catering to wholesale, retail, and export markets across Germany. Each unit is securely packed using industrial-grade materials to prevent transit damage during transportation. Our packing & dispatch team coordinates timely shipments using reliable transport services, covering main domestic markets and ensuring on-schedule delivery to dealers, distributors, traders, and service providers nationwide.

FAQ's of GE Fanuc IC693CPU311W PLC:

Q: How can the GE Fanuc IC693CPU311W PLC be expanded for additional I/O requirements?

A: The PLC supports expansion through compatible additional modules, making it ideal for scalable automation projects that require future upgrades or increased input/output capacity.Q: What applications are ideal for the IC693CPU311W in industrial settings?

A: This PLC is best suited for process control and automation tasks in manufacturing plants, process industries, and other demanding environments requiring reliable, programmable control and high efficiency.Q: Where can the GE Fanuc IC693CPU311W PLC be installed?

A: It is designed for flexible installation, allowing mounting on standard DIN rails or panels, making it suitable for numerous control cabinets or machine panels in industrial environments.Q: What is the process for programming the IC693CPU311W PLC?

A: Programming is accomplished using Proficy Machine Edition or Logicmaster 90-30 software. Users connect via the RS-485 port, upload their control logic, and verify operation using onboard LEDs and diagnostic tools.Q: When should battery backup be used in this PLC?

A: Battery backup should be leveraged when non-volatile data retention is necessary during power interruptions, ensuring user programs and data are preserved for uninterrupted operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in GEFANUC PLC AND HMI Category

GE FANUC IC200MDL640F

Price 5500 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Black

Connector Type : Screw Terminals

Humidity % : 5% to 95% noncondensing

Size : Standard

GE FANUC IC200PWR102R

Minimum Order Quantity : 1 Piece

Color : Grey

Connector Type : Screw Terminal

Humidity % : 5% to 95% (noncondensing)

Size : Standard Compact

GE FANUC IC200UDR001-BC

Minimum Order Quantity : 1 Piece

Color : Grey

Connector Type : Screw Terminals

Humidity % : 5% to 95% (noncondensing)

Size : Compact

GE FANUC IC200UEX222-B

Minimum Order Quantity : 1 Piece

Color : Black / Grey

Connector Type : Screw Terminal Block

Humidity % : 5% to 95% NonCondensing

Size : Standard

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry